FRUIT & VEGETABLES

Hardly any other area of the food market is as dynamic as the production and trade of fruit and vegetables. Three key trends in particular are responsible for this. Firstly, fruit and vegetables play a key role in the realization of a lifestyle geared towards health and longevity. The demand for organic products is growing rapidly and, above all, faster than supply, making agriculture based on strict organic criteria a highly profitable segment. This development goes hand in hand with a pronounced consumer awareness of the quality of fruit and vegetables and an increasing willingness to pay for particularly tasty products or "superfood" products with special health properties. The fresh fruit and vegetable department plays a decisive role in how a PoS is judged by consumers. The range is expanding to include innovative forms of packaging and convenience elements such as fresh-cut fruit and snackables.

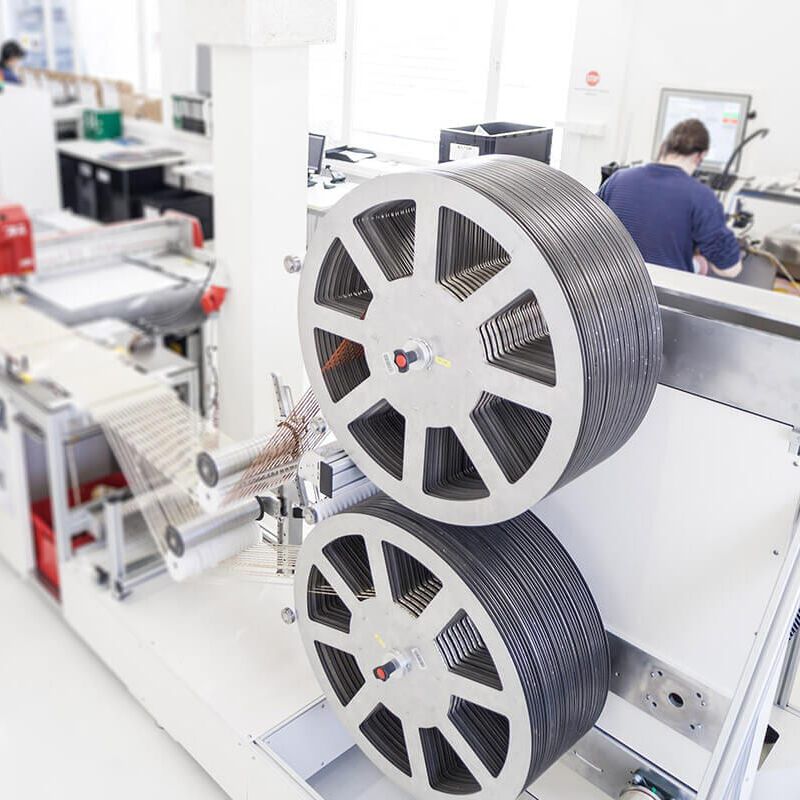

Sustainable design of production chains for fruit and vegetables

At the same time, ecological and socio-economic aspects of sustainability are becoming decisive product characteristics, especially for fruit and vegetables. On the one hand, this includes the careful use of soil, water and energy as part of regenerative agriculture and the reduction of waste, chemical consumption and packaging materials. On the other hand, seasonal and regional purchasing to strengthen local agriculture and reduce CO2 emissions are key decision-making factors for consumers, especially when it comes to fruit and vegetables.

Additionally, producers in this sector must deal with the consequences of climate change in the long term, for example by adapting and expanding their product range to include climate-friendly varieties. These trends place high demands on the geographical and structural design of purchasing, production and supply networks, the guarantee of high quality of perishable goods and the creation of a high level of security and transparency in the verification of sustainability and product quality throughout the entire production chain.

©Yakobchuk Olena/adobe.stock

Our consulting services in the fruit and vegetables sector

EFESO supports companies involved in the production and trade of fruit and vegetables in the following areas, among others:

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/e/csm_EFESO_sustainability_sustainable_products_53f73ed7fd.jpg)