TREND & RISK MANAGEMENT IN FOOD PRODUCTION

Countering trends and risks as a food producer with security

Today, companies in the food and beverage industry are confronted with a growing number of risks and trends that increasingly have to be dealt with in parallel and with a short time horizon. The particular challenge is therefore not only to identify the key developments at an early stage, but also to translate them quickly and precisely into concrete action programs.

EFESO supports companies in developing structures, systems and processes that enable them to make and implement the right decisions under high strategic pressure:

- Organization of risk management: development of a robust organizational and control structure as well as a KPI system for integrated and agile risk management.

- Risk assessment: implementation of due diligence processes for risk identification in mergers and acquisitions and assessment of sustainability risks for integrated programs.

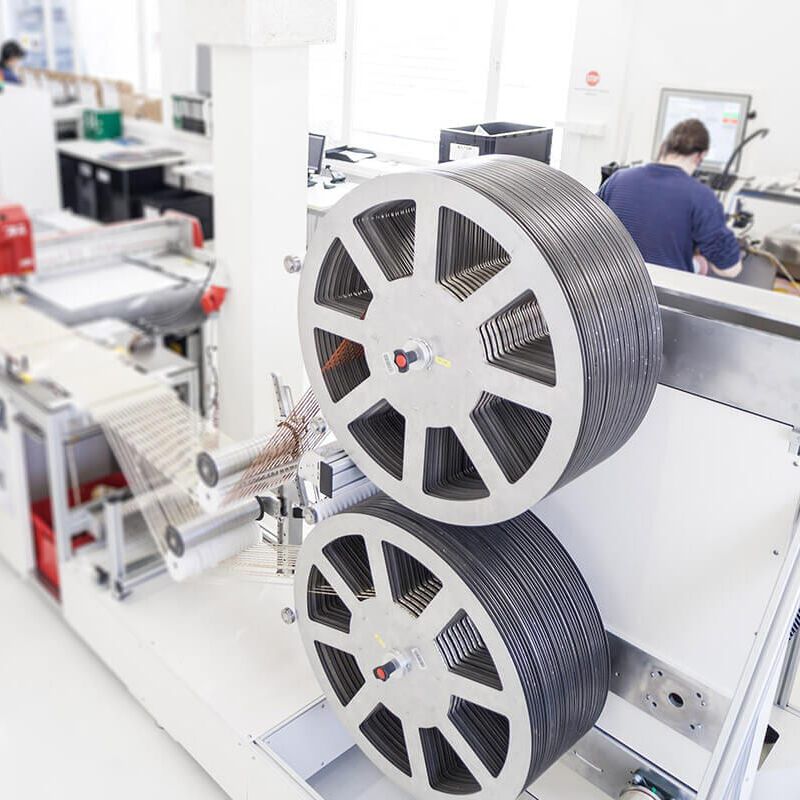

- Early detection: use of AI-supported, data-based early warning systems to identify trends and risks at an early stage and derive targeted measures. Increase transparency throughout the entire supply chain by using innovative solutions such as supply chain towers and digital process twins.

- Increasing resilience: strategic alignment of the network with regard to key long-term trends and implementation of active risk management; flexibilization and increasing the adaptability of resources and processes.

TREND & RISK MANAGEMENT –

Analyze and control relevant developments in the market with innovative technologies and methods

Further solutions for the food & beverage industry

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/e/csm_EFESO_sustainability_sustainable_products_53f73ed7fd.jpg)