Our services for optimizing your cost structures

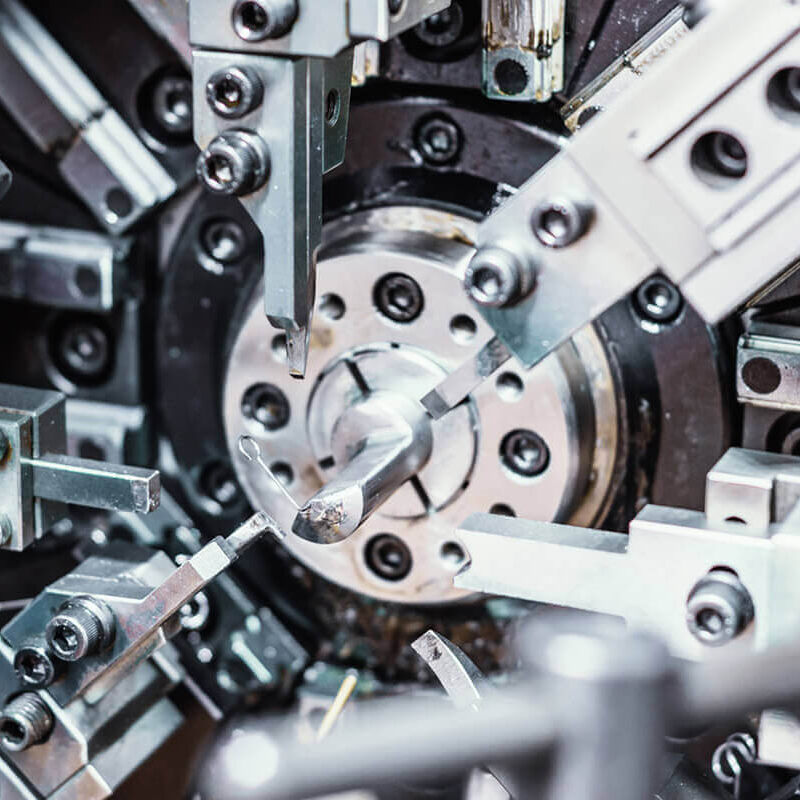

EFESO supports companies in identifying and eliminating cost and expense drivers along the entire value and supply chain. In doing so, we look at all areas of the company to identify potential savings – from the supply chain and intralogistics (Inventory Cost Program) to product development (Value & Cost Engineering) and manufacturing (Industrie 4.0 Instant Payback).

Our range of services includes:

- EFESO Cost Reduction Program: integrated approach for effective optimization of cost structures along industrial value chains.

- Zero-Based Organization: cost-conscious redesign of your organisation.

- Cost Value Engineering: aligning cost management for the future.

- Cost down - performance up: achieving lean and resilient cost structures.

- Product Industrialization & Ramp-up Management: closing gaps in the product engineering process (PDP).

For these topics, we develop needs- and industry-specific solutions for the sustainable optimization of cost structures and the sustained strengthening of competitiveness. In doing so, we always make sure that they are anchored in the profit and loss statement, so that cost reduction measures are directly reflected in your company's balance sheet.

Project: Product cost reduction in the business unit of a family-owned company (1 billion turnover worldwide p.a.). Holistic cost reduction programme to stop losses and sustainably improve processes and organisation.

Results: Introduction of a shop floor management as well as production planning led to a

- Productivity increase of 22% in the direct and indirect areas

- Reduction of backlog by almost 100%

- Reduction of internal defect costs by more than two thirds

- Introduction of premium wages

- Reduction of consumables by 10%

- Increase in inventory turnover rate by 40%

The implementation of a one-piece flow on the assembly line resulted in an increase in the

- EBIT margin by +8.5%

- EVA margin by +7% after one year.