Product Machining Excellence

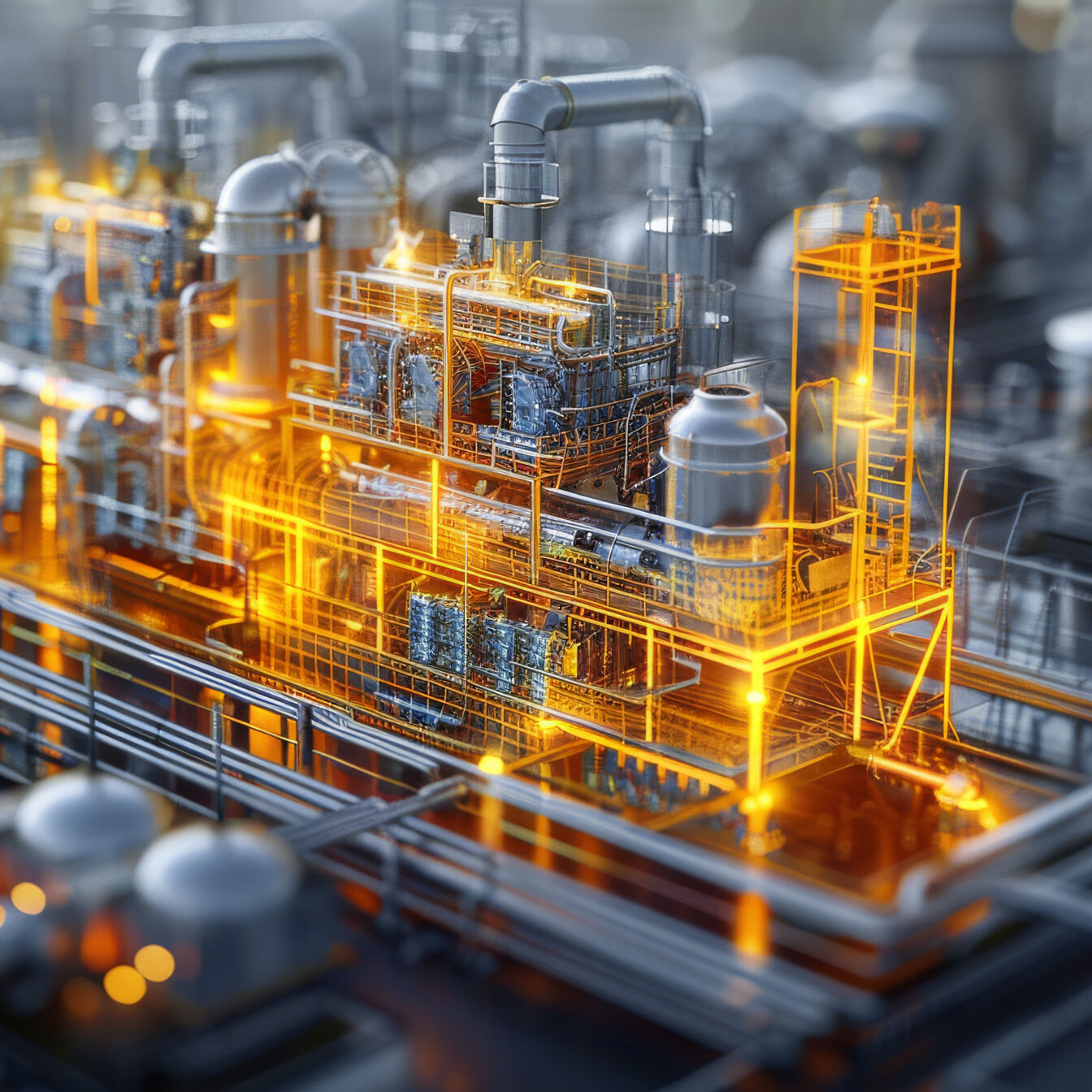

In manufacturing, individual machines – or in cases of exceptionally high demand, even the entire machine fleet – often turn out to be bottlenecks and significant cost drivers. Moreover, replacing machinery and equipment is capital-intensive, resulting in a direct negative impact on cash flow.

Therefore, enhancing the performance of existing machines and equipment plays a central role in EFESO’s product excellence initiatives. With a holistic approach to cycle time optimization and increasing the OEE of existing machinery, we achieve significant improvements without additional CAPEX investments. In doing so, we rely primarily on two particularly advanced, self-developed and refined methods: video analysis and “Software-Based Machine Tuning.”

Faster, smarter, more efficient: boost your production performance!

The EFESO Performance Booster shows you how to achieve big results with small adjustments.

AI-Based video analysis in manufacturing

The video analysis uses AI-powered software for time-synchronized camera sequences and multi-image analysis, which has already been used in more than 600 analyses. It is ideally suited for analyzing environments with numerous machine movements or peripheral activities (e.g., robots) – in machining, assembly, and any kind of automation across multiple industries.

Our project footprint in video analysis

This type of video analysis can identify and evaluate weaknesses and optimization potential with exceptional depth. In general, five application areas can be defined where video analysis provides particularly significant optimization leverage:

The value of using video analysis is demonstrated by the following example:

PROJEKT EXAMPLE

Video analysis of existing infrastructure enables an increase in output of at least 9%

Initial situation

Challenges in a series or large-scale production:

- Urgent need to increase capacity

- Reduction of cycle time

- Bottlenecks in the manufacturing process

- Capacity requirements for new products (identify performance reserves)

- Quality optimization (e.g. high reject rate)

- Availability problem (unplanned downtime due to process problems)

Approach / method

- Multiple camera installation & video recording

- Sequencing with video-analysis tool

- Idea documentation, based on micro potentials

- Review of ideas with customer team

- Implementation plan development (including realization)

Customer Value Added

Make hidden potential visible

Our AI-powered video analysis reveals untapped efficiency potential in your production – beyond the visible.

Software-Based Machine Tuning in production

“Software-Based Machine Tuning” is a specialized method for improving the cycle times of existing CNC machines without additional investments in hardware. Following a preliminary analysis of the machine software, an additional solution is installed that enables adaptive control and AI-supported real-time data analysis.

Our project footprint in Software-Based Machine Tuning

The following example illustrates how existing potential can be fully maximized:

PROJECT EXAMPLE:

software-based machine tuning

Initial situation

Challenges in a series or large-scale production:

- Urgent need to increase capacity

- Reduction of cycle time

- Bottlenecks in the manufacturing process

- Capacity requirements for new products (identify performance reserves)

- Quality optimization (e.g. high reject rate)

- Availability problem (unplanned downtime due to process problems)

Approach / method

- Quick check and pre-analysis of machine software

- Offline preparation of software installation

- Software installation and implementation of tools at the machines for adaptive feed control with smart real-time data analysis

- Cut-check data to confirm efficiency improvement

Customer Value Added

Boost machine performance

Increase your CNC machine efficiency with software-based tuning – no new hardware needed.

With our Performance Booster, we optimize existing production systems in just a few weeks.

Through software tuning, automated visual analyses and other smart approaches, we help our customers to achieve double-digit savings - without having to purchase new machines.

CONTACT

End-to-end solution portfolio for product excellence