Consulting partner of the high-tech and electronics industry

As a globally active operations consultancy, EFESO combines strategic and operational intelligence to realize industry-specific solutions for these and other tasks. Use this expertise to successfully guide your company through transformation and set it up in the best possible way for the future.

With the EFESO team, you can improve processes in direct and indirect areas such as development, purchasing, production and logistics. Whether in the context of global business excellence programs for performance enhancement, for optimization of cost structures or to deliver capability – we always focus our work on achieving measurable and significant results together with you.

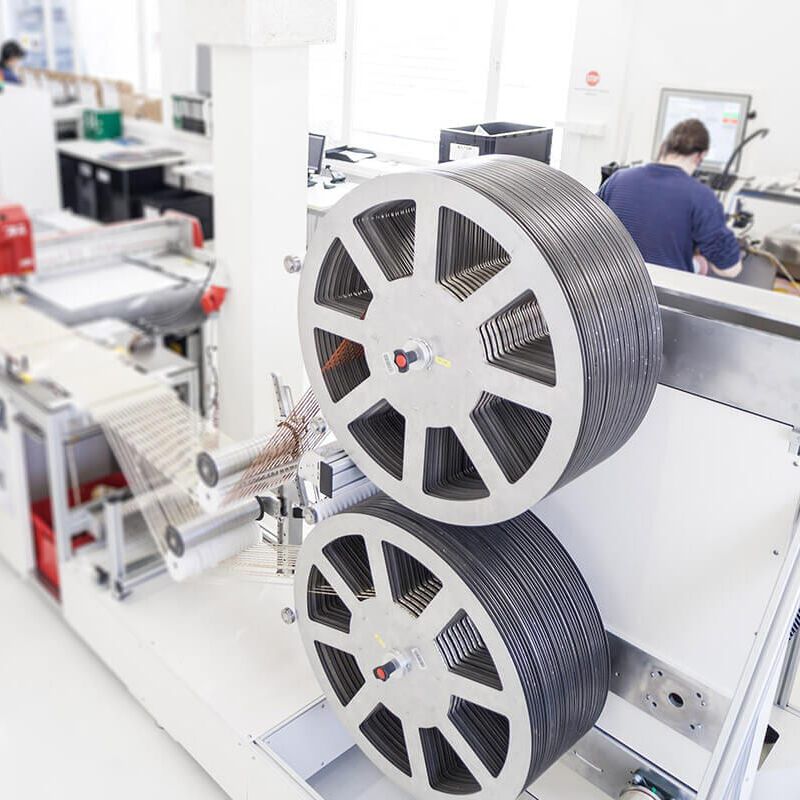

In addition to the above, we can help you successfully leverage digitization and automation. Here, the focus can be on current challenges, such as on the development and cost-efficient distribution of high-quality products. Furthermore, we configure with you your Future Factory, which corresponds to the framework conditions of your organization and your market environment.

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)

![[Translate to English:] Warehouse 4.0, Intralogistik 4.0, Logistik](/fileadmin/user_upload/intralogistik-2030-roi-beratung.jpg)