Consulting partner of the aerospace industry

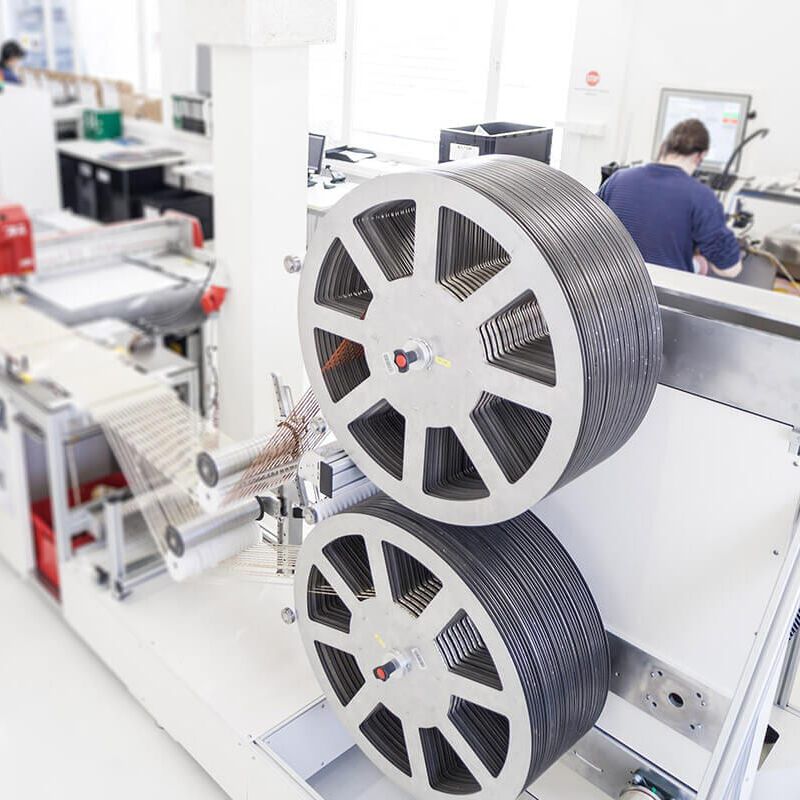

There are plenty of opportunities to turn these challenges into business successes: for example, emission-free propulsion technologies, innovative aviation fuels (SAF) and composite materials support the implementation of sustainability goals in the aviation sector. At the same time, space travel is diversifying into future-oriented business areas, such as space tourism or in the context of new missions to Mars and the moon. However, existing strengths can also often be expanded, for example by using AI (artificial intelligence) to simulate, develop and manufacture new products.

Take advantage of EFESO's industry-proven strategy and implementation expertise. Design efficient development and production networks, resilient and sustainable supply chains with us and align your value creation structures for the future and growth! Our services for aerospace companies include:

- Global Operational Excellence Programs (OPEX) to improve performance.

- Cost optimization for products, Production and logistics.

- Improving development processes in (global) R&D organizations.

- Increasing the efficiency of supply chain management, for example to fulfill short-term push initiatives for deliveries.

- Support in the planning and development of new locations (factory ramp-up).

- (New) design of existing (lean) processes in the factory, e.g to stabilize and increase delivery key figures.

We also advise aircraft manufacturers and their suppliers on the digital transformation of their processes along the entire value chain. We support for example in the acquisition of new business (Proposal-Support), in program and offset management - or configure a "Future Factory", which meets the requirements of the organization and the market environment of the company.

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)