Sustainable Transformation

In the manufacturing industry, aligning processes, products and supply chains with sustainability goals means reducing resource consumption, ensuring recyclability throughout the entire product life cycle and avoiding negative effects on people and the environment.

Inefficient industrial processes cannot be sustainable: the transformation therefore requires, on the one hand, the use of classic instruments to increase efficiency and transparency, avoid waste and digitalization. On the other hand, it forces an expanded view of the value creation network and its social, institutional, and ecological footprint.

Sustainability Assessment & Roadmap

A sustainable transformation starts with the question of whether the company's sustainability goals can be achieved within the given framework or whether structural and procedural adjustments are required.

EFESO's Sustainability Assessment provides the necessary transparency to answer these questions. Based on best practices and established standards, all transformation-relevant dimensions, projects, and initiatives are considered in a networked manner:

- Business model & strategy

- Management system & organization

- Culture & competencies

- Product development & product life cycle

- Production, supply chain & operations

Based on the sustainability assessment, we calculate the current carbon footprint and define sustainability targets, particularly regarding resource efficiency, decarbonization, the circular economy, digitalization, and the introduction of service-based business models. We prioritize the topics in a materiality matrix, define the relevant initiatives in a sustainability agenda and bring them together in an implementation-oriented roadmap.

The initiatives are aimed at improving sustainability and cost balance on the one hand and creating strategic and operational advantages in terms of growth and competitiveness on the other. These include, for example, improving the marketability of products, developing new business models, securing access to resources, increasing resilience, using technology, or identifying risks, investment opportunities and funding possibilities.

In addition, we use the Transformation Roadmap to ensure comprehensive transparency regarding regulatory, macroeconomic and technological framework conditions.

Realizing transformation

EFESO focuses on the following core areas when implementing sustainable transformation initiatives:

- Product portfolio & lifecycle: optimization and further development of the Product portfolio. Focus areas: a product design that is geared towards environmental protection / resource conservation, the product lifecycle, and its extension through smart products. Creation of business models and business case calculations in which economic goals are combined with ecological and social responsibilities.

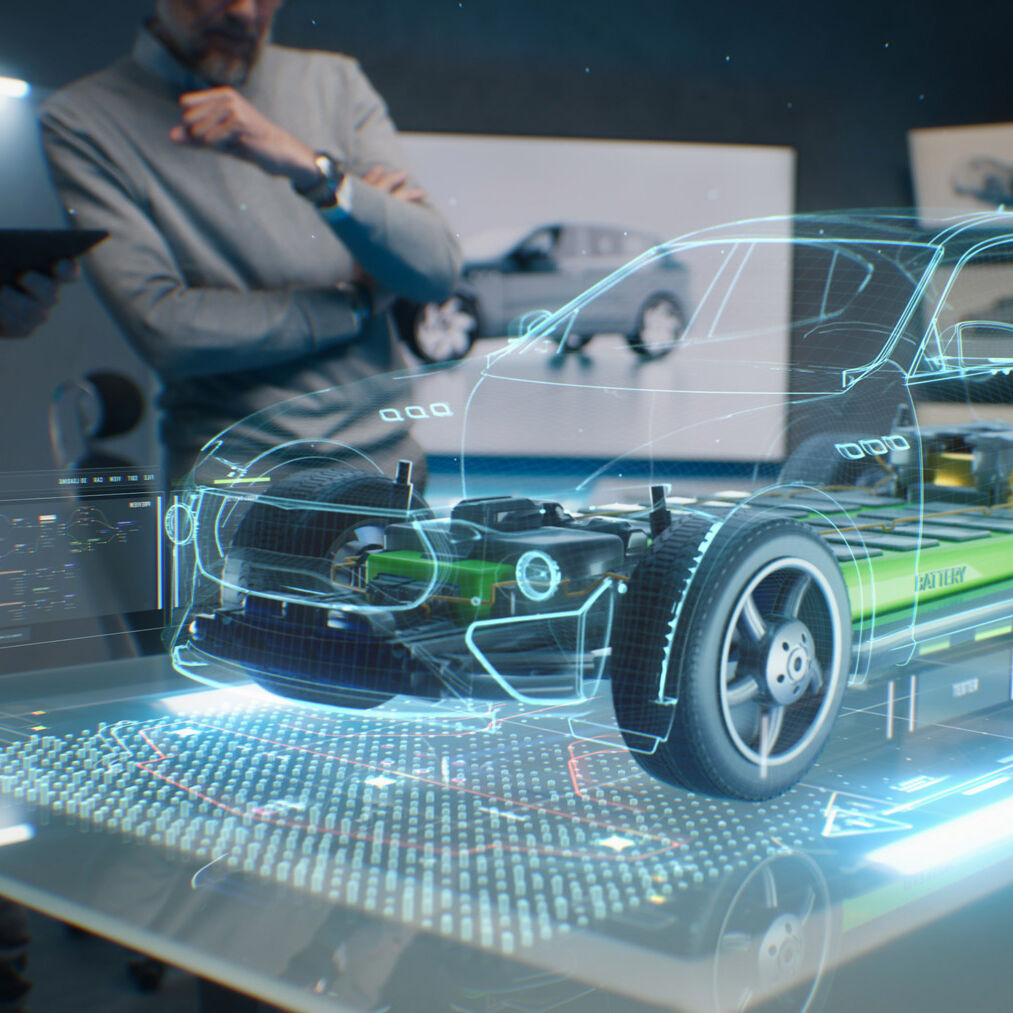

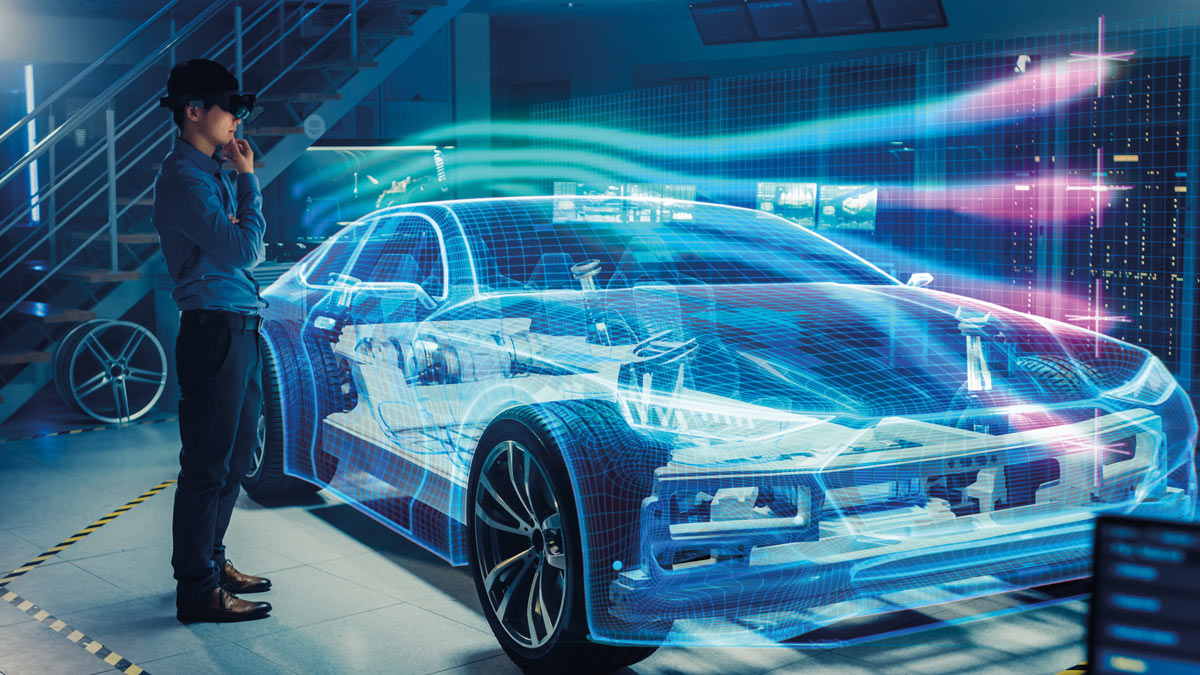

- Dematerialization of business models: use of smart technologies to digitalize business models and processes and to reduce the consumption of resources in the production, logistics and operation of hardware.

- Manufacturing & Supply Chain Footprint: adaptation or realignment of value creation networks and partnerships, e.g. regarding relevant ratings, compliance, process control and monitoring, the procurement of renewable energy, the collaborative reduction of the ecological footprint or financing options.

- Future Factory: implementation of innovative, modular concepts for the design of energy- and resource-efficient, flexible, and circular production systems. This includes, for example, the reuse of components through remanufacturing and integration into the implementation of digitalization and automation strategies.

- Operational Excellence & Change: development of a learning and continuously improving organization with regard to sustainability goals as well as support for organizational and cultural adjustments through focused change management, training and capability building.

- Value Network: identification of improvement potential for sustainability KPIs in the partner / supplier network. Value-added-oriented connection of stakeholders, for example in the creation of transformation roadmaps or the joint identification and utilization of cost-cutting potential.

BEST PRACTICE: SUSTAINABLE TRANSFORMATION

Our Pest Practice case studies describe results and further details from EFESO sustainability projects in different industries.

Expert article: How the topic of sustainability can be used as a value creation lever for portfolio companies.

Sustainability risk integration in the procurment of a car manufacturer.

Digitalization offers opportunities for the forestry and packaging industry to sharpen its sustainability focus.

Premises and fields of action for the development of sustainability strategies in industry.

Interview about “EU taxonomy” with Tim Ballenberger, Senior Consultant at EFESO and Florian Santolini, Regional Director at kShuttle.