Sustainable Supply Chain & Footprint

Sustainability potential can be leveraged at all stages of the supply chain – from the extraction of raw materials to pre-production, transportation, processing and delivery of the end products to the customer through to disposal or recycling. Companies must therefore understand the impact of their global network on the social and ecological environment, consider dependencies, framework conditions and market structures and develop effective approaches to reduce negative environmental effects throughout their entire value creation network.

External risks and trends to which companies are exposed and which can be addressed in the context of sustainability must be considered – e.g., the availability of renewable energies or ensuring that supply chains are ecologically and ethically sound. At the same time, it is important to analyze the company's impact on the various dimensions of sustainability, for example regarding decarbonization, biodiversity, environmental pollution, work standards or the careful use of local resources.

The integrated consideration of both perspectives forms the framework for developing scenarios, quantifying relevant factors, and prioritizing topics relating to social and environmental sustainability.

Low Impact Supply Chain

National and international legal standards require companies to reduce emissions in their upstream and downstream supply chain. This means that companies share responsibility for areas that they cannot influence directly, the "Scope 3 upstream" emissions. Intensive involvement of suppliers is therefore necessary in order to gain transparency about emissions and to be able to reduce them with a view to the entire global operations footprint.

EFESO's approach aims to optimize value creation networks with a view to reducing the carbon footprint and increasing resilience. To this end, we extend the classic approaches for planning and managing supply networks with specific methods for improving the sustainability balance:

- Strategy & risk management: establishing sustainability goals in the network and resolving conflicting goals between efficiency and resilience; assessing site-specific sustainability benefits and risks and integrating them into decision-making processes and developing mitigating approaches.

- Transparency: ensuring comprehensive transparency on key sustainability issues such as Scope 3 footprint, behavior and compliance of n-tier suppliers, location factors or external trends and framework conditions.

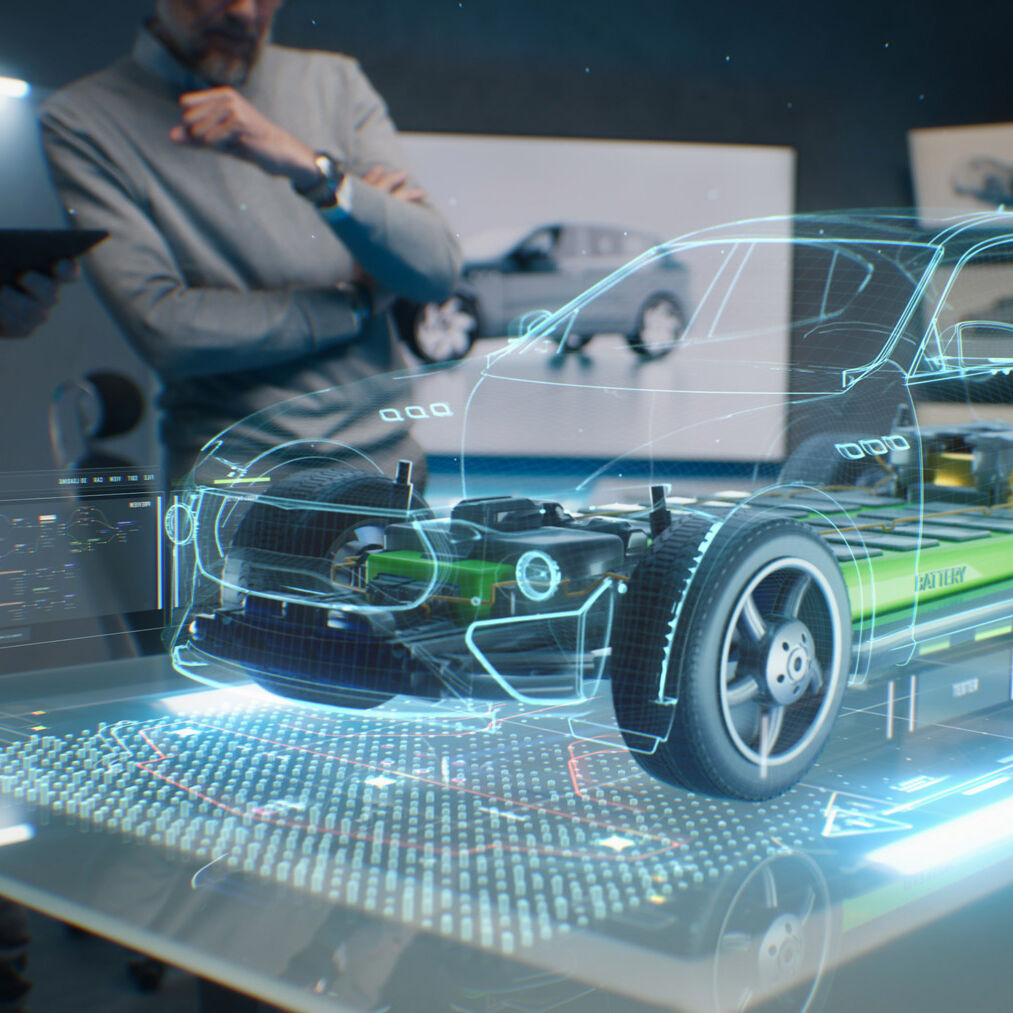

- Process digitalization: use of digital technologies such as Digital Supply Chain Twin or Supply Chain Control Tower to optimize and simulate the entire value chain about sustainability criteria; increasing transparency and resilience as well as saving resources through the digitalization of physical processes.

- Circular Supply Chain: consideration of the circular economy when selecting a location with regard to factors such as proximity to recycling and infrastructure operators, access to recycled raw materials or return planning for products in circulation (see also Future Factory / Reverse Factory).

- Sustainable procurement: Alignment of the supply chain based on sustainability targets with a focus on procurement; integration of sustainability issues and drivers into procurement strategies and processes; target definitions for Scope 2 and Scope 3 emissions and identification of potential for improvement in suppliers' ESG performance.

- Value network: identification of optimization potential for sustainability KPIs in the partner / supplier network. Value-oriented connection of stakeholders, for example in the realignment of value chains according to a “local-to-local” focus or in the design of global transport tracks.