DAIRY PRODUCTS

Innovations in the dairy industry are being driven by several intensifying trends. Changing eating habits are the main reason for this. There is a strong focus on health aspects: ingredients such as sugar are increasingly viewed critically by consumers, which makes it necessary to develop sugar-reduced recipes based on new cultures and enzymes.

On the other hand, hybrid products that combine milk with plant-based elements such as oats and almonds, or completely dispense with animal ingredients, are becoming increasingly popular. Alternative methods, such as the use of microflora and fermentation to produce animal-like milk proteins, are meeting with great interest from consumers. Changing health awareness and an increased focus on the role of food in effective health management are rapidly increasing the demand for functional foods such as probiotic fermented milk products and protein milk drinks.

Effectively managing the need for change in the dairy industry

In addition, innovative approaches are emerging around the convenience trend, which is reflected in new packaging methods, extended shelf life of fresh products and individualized preparation options. This development corresponds with consumers' desire for new impulses in the enjoyment of dairy products: new flavors, changes and differentiations in textures and unusual product combinations are opening up new ways of appealing to customers.

Conversely, the inflation-induced rise in food prices has boosted demand for private labels for basic products such as milk and butter. These partly contradictory trends are leading to an explosion in complexity and creating an enormous need for adaptation in the dairy industry. This ranges from the reorientation of research and development, the purchase of new raw materials and the introduction of new production and supply chain concepts to the integration of alternative sales, service and marketing strategies.

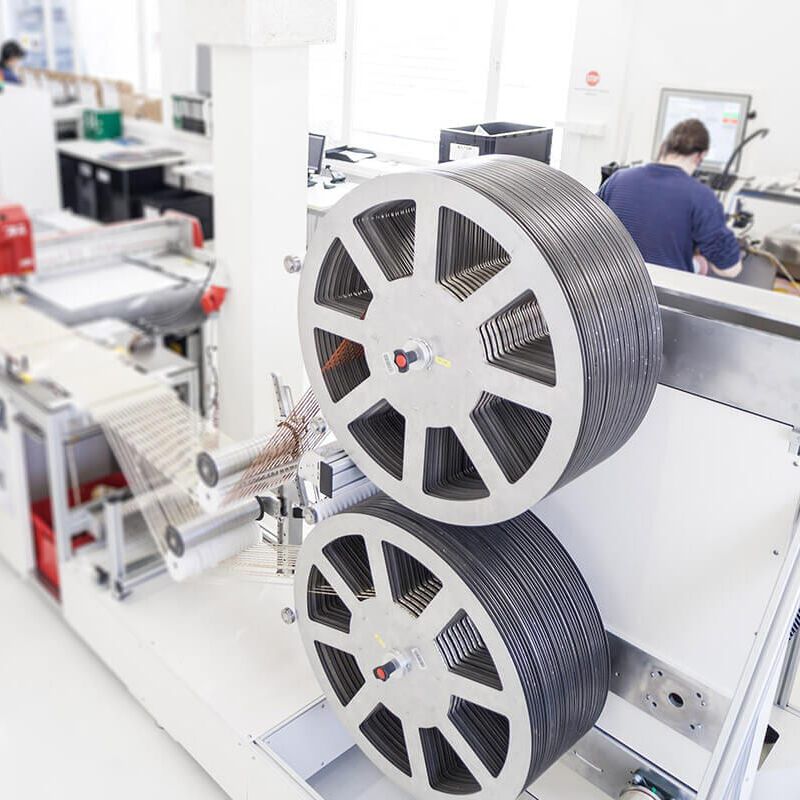

©warloka79/adobe.stock

Our consulting services for the dairy industry

EFESO supports companies in the dairy industry in the following areas, among others:

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/e/csm_EFESO_sustainability_sustainable_products_53f73ed7fd.jpg)