"Design to X" (DtX) in the machinery and plant construction sector

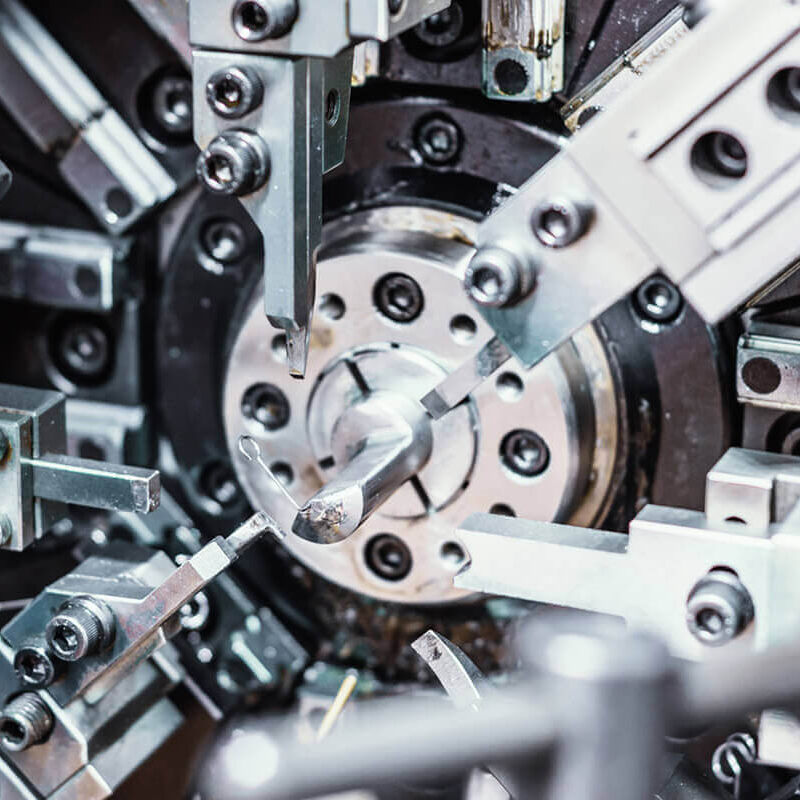

The industry faces conflicting challenges in the design of its machines and systems: precise values from target costing must be reconciled with the high demands on quality and functionality. Customer-specific requirements drive variant diversity and make it difficult to reduce costs through standardization. With the consistent application of various design specifications ("Design to X"), these and other contradictory objectives can be resolved, for example with regard to costs, sustainability, and product longevity.

"Design to X" supports manufacturing companies

in finding the balance between different objectives.

ROI-EFESO guides companies from the machinery and plant construction sector safely and purposefully through all facets of product design. For example, a "Design to Cost" initiative reveals unexpected levers in material and production costs, while at the same time making the product significantly more sustainable ("Design for Sustainability").

Results

Initiatives with a focus on "Design to X" achieve the following results for companies in the sector (selection):

- 15% - 30% Savings in the manufacturing process

- 20% - 35% Reduction of the investment costs

- 7% - 35% Savings at direct materials

Success factors for "Design to X" in machinery and plant construction

When working with ROI-EFESO, companies focus on the following fields of action:

- Target definition and prioritization: definition of specific and measurable targets for "X"; harmonization of contradictory targets through prioritization and target conflict management.

- Profitability toolbox: application of precise methods and tools to improve the product in the preferred dimensions such as production and assembly, sustainability, total costs. Usage of tools such as Product Benchmarking, Design Thinking, Quality Function Deployment (QFD) and Cost Engineering as well as technologies (e.g. digital twins, simulations, and AI) to forecast and control target achievement.

- Modularization and standardization: development of a modular system for products in order to reduce the number of variants and exploit economies of scale (example: uniform drive, control and frame units for different machine models); consideration of the reusability of components for different functionalities.

- Integration: early integration of production, purchasing, quality and supply chain management into the design process in order to resolve conflicting objectives at an early stage.

Further services for companies in the machinery and plant construction industry

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)