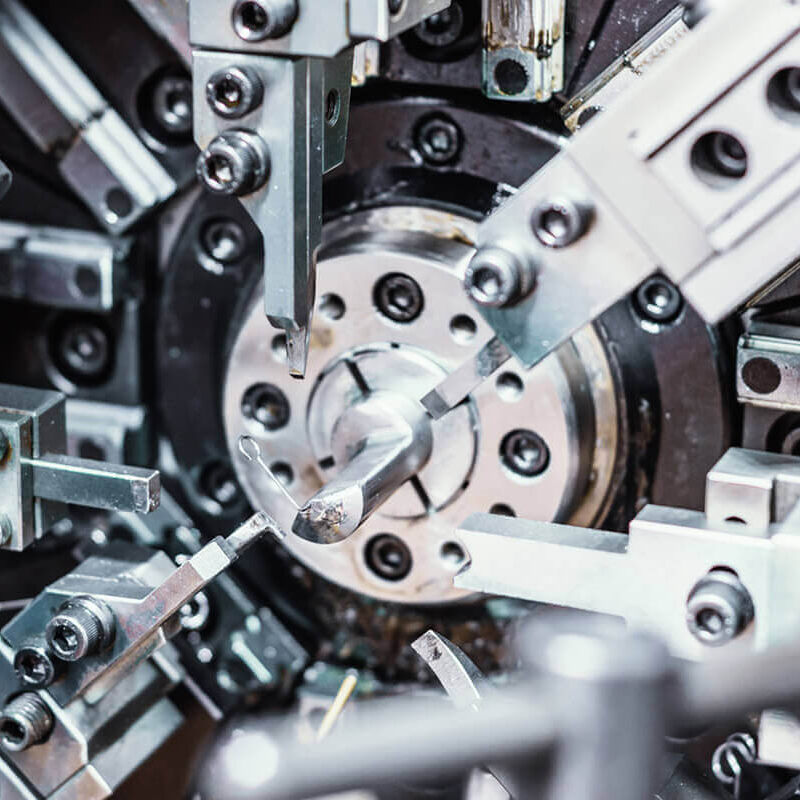

Strengthening and securing global competitiveness in the machinery and plant construction industry

The machinery and plant construction sector operates in a globally competitive environment. In order to maintain and expand their position, companies must adapt their value chains to highly volatile markets and rapidly changing customer requirements. It is also to be expected that rising labor costs and stricter environmental protection requirements will further increase the pressure on profitability.

Global competitiveness is the result of

excellent products, efficient processes, and strategic resilience.

With ROI-EFESO, companies in the machinery and plant construction area strengthen their competitiveness. With a worldwide consulting network and comprehensive expertise in product development, procurement, production, and supply chain management, we offer suitable solutions for global value chains and local production.

Results

In projects with ROI-EFESO, machinery and plant construction companies achieved these results to improve their products and operations processes (selection):

- 20% - 40% Reduction in throughput times

- + 20% - 30% Increase OEE

- + 2 - 10 Increase EBIT margin

Key factors for competitiveness in the machinery and plant construction business

In cooperation with ROI-EFESO, companies in the industry focus to further development in the following fields of action:

- Unique products: development of products that are "best in class" in terms of functionality and technology. Directing product design on “Design to X,” so that it makes a significant contribution to manufacturability, sustainability, and profitability.

- Development of a “Design for Production Network”: linking R&D processes with manufacturing networks. Objective: development of products that can be assembled on existing equipment in a time- and cost-efficient manner.

- Balancing price and cost pressure: expansion of the Product portfolio to include low-priced "good enough" products in response to Chinese competitors. Approaches: product cost reduction by adapting the specification, cheaper procurement ("best cost sourcing") and more efficient production ("best cost manufacturing").

- Safeguarding supply capability: building resilient and flexible supply networks, for example according to the approach "from the region for the region"; minimizing risks in the supply chain and improving responsiveness to market requirements.

Further services for companies in the machinery and plant construction industry

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)