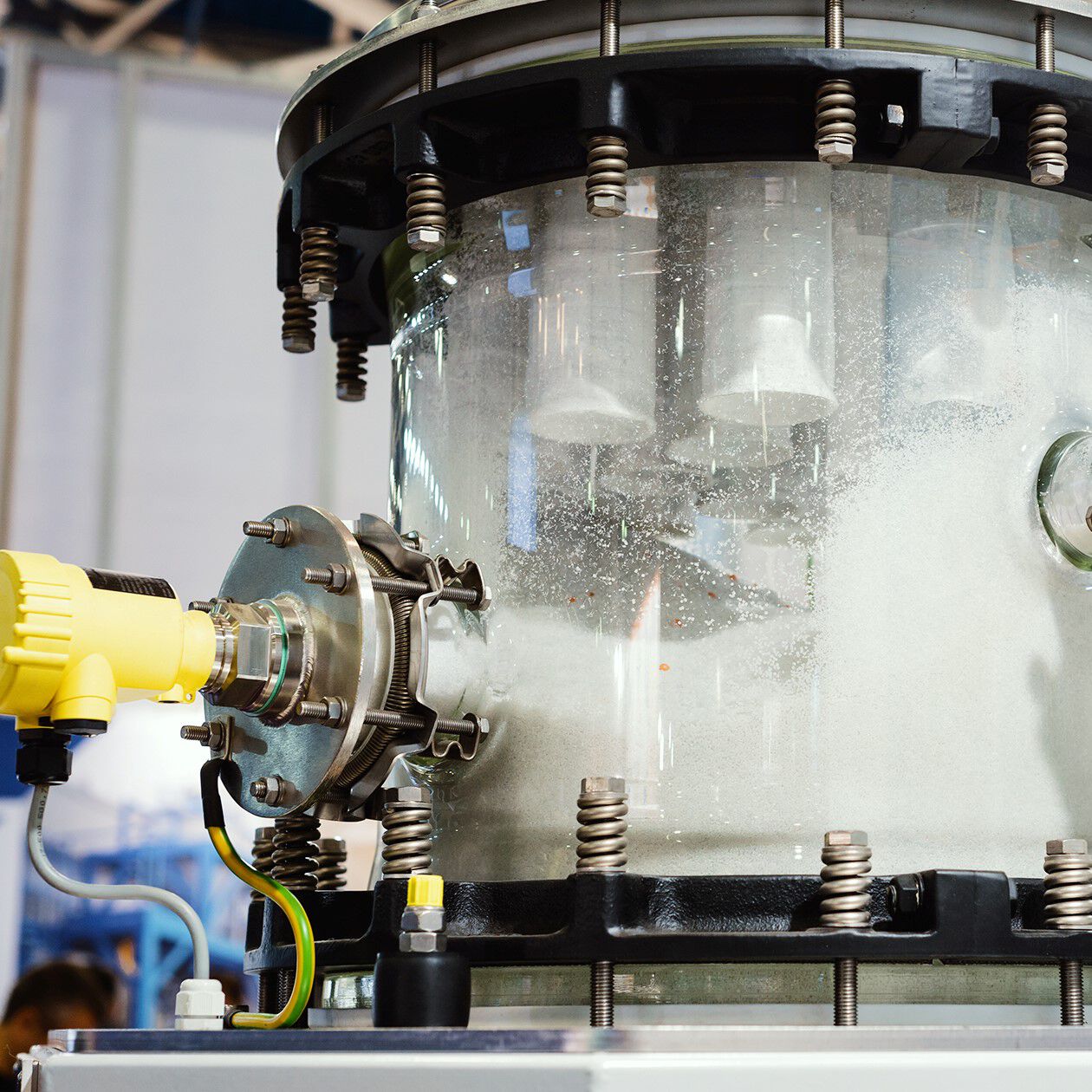

Companies in the chemical industry are confronted with rising energy costs and strict regulatory measures, particularly in the European Union (EU). The 2023/2024 recession will exacerbate this situation with strong cost pressure, which will be further increased by the rise in imports into the EU.

At the same time, the industry needs adequate solutions to the challenges of sustainability and decarbonization. However, the horizon here extends far beyond the EU - e.g. in the area of hydrogen production, where China and the Middle East are emerging as future centers and dominant players in the value chain.

In addition to these market-shaping developments, the significant shift in the focus of global investment towards the chemical industry in the United States should not be underestimated. This shift is favored by regulatory measures and CapEx subsidiaries in conjunction with lower TCO for the operating phase. Sustainability factors are therefore becoming increasingly important in investment decisions, for example as an element of net present value calculations or in the form of scoring models for projects.

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)

![[Translate to English:] Warehouse 4.0, Intralogistik 4.0, Logistik](/fileadmin/user_upload/intralogistik-2030-roi-beratung.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/e/csm_EFESO_sustainability_sustainable_products_53f73ed7fd.jpg)