Operational Excellence in the Chemical Processing Industry (CPI)

OPEX (Operational Excellence) projects in the chemical industry are geared towards a comprehensive improvement of the respective company's value creation processes. In the European environment, energy prices, feedstock and regulatory framework conditions put companies at a disadvantage in global competition, particularly compared to the USA and Asia. This requires the best possible use of resources to maintain competitiveness.

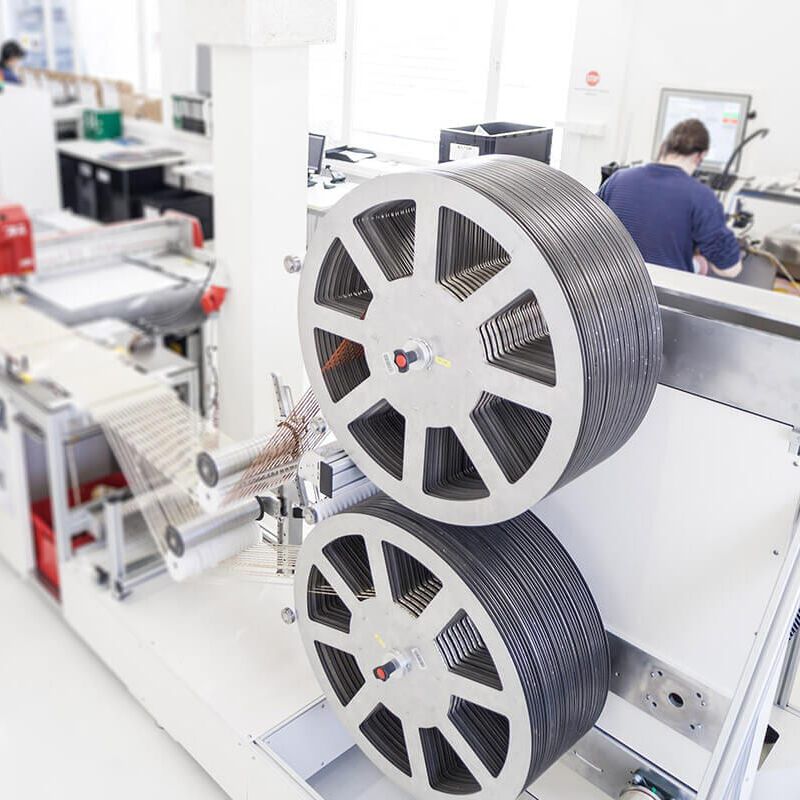

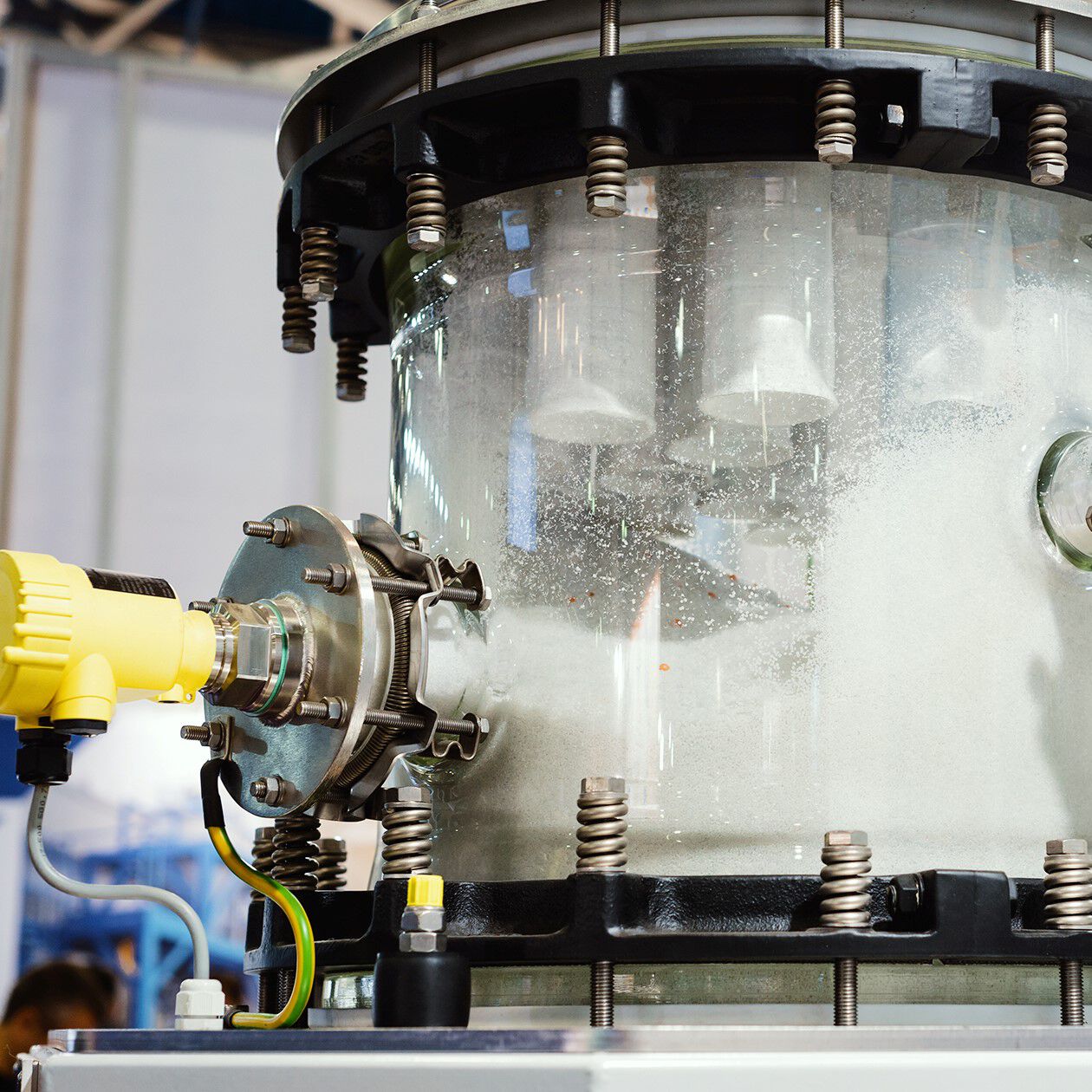

At the same time, holistic optimization approaches offer plenty of scope to leverage significant potential. For example, driving parameters can be optimized in a very targeted manner using digital tools: yield, rate, batch cycle times and ramp-up /ramp-down can be improved. In addition, many potentials can be activated through standardization and system availability losses can be effectively addressed – for example by optimizing cleaning and product changeover times or using autonomous management / maintenance systems. In addition, the interface between production and maintenance is an area that significantly determines the level of performance and availability of a system and offers starting points for further developments.

Advancing OPEX cross-functionally

In the past, chemical companies often focused on selective improvement initiatives, e.g. separately for production or maintenance. Today, they are increasingly moving towards setting up holistic OPEX programs. This cross-functionality is also an important prerequisite for establishing truly sustainable and comprehensive improvements. Particularly with a view to sustainability, these programs go hand in hand with the development of an internal infrastructure for change. In other words, targeted investment is made in internal expertise in order to autonomously drive the continuous improvement process forward.

CLIENTS

Further services for the chemical industry

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)

![[Translate to English:] Warehouse 4.0, Intralogistik 4.0, Logistik](/fileadmin/user_upload/intralogistik-2030-roi-beratung.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/e/csm_EFESO_sustainability_sustainable_products_53f73ed7fd.jpg)