- Main topics

- Company

- Competences

- EFESO competences overview

- Cost reduction

- Digitalization, Industry 4.0 and IIOT

- Manufacturing and Logistics

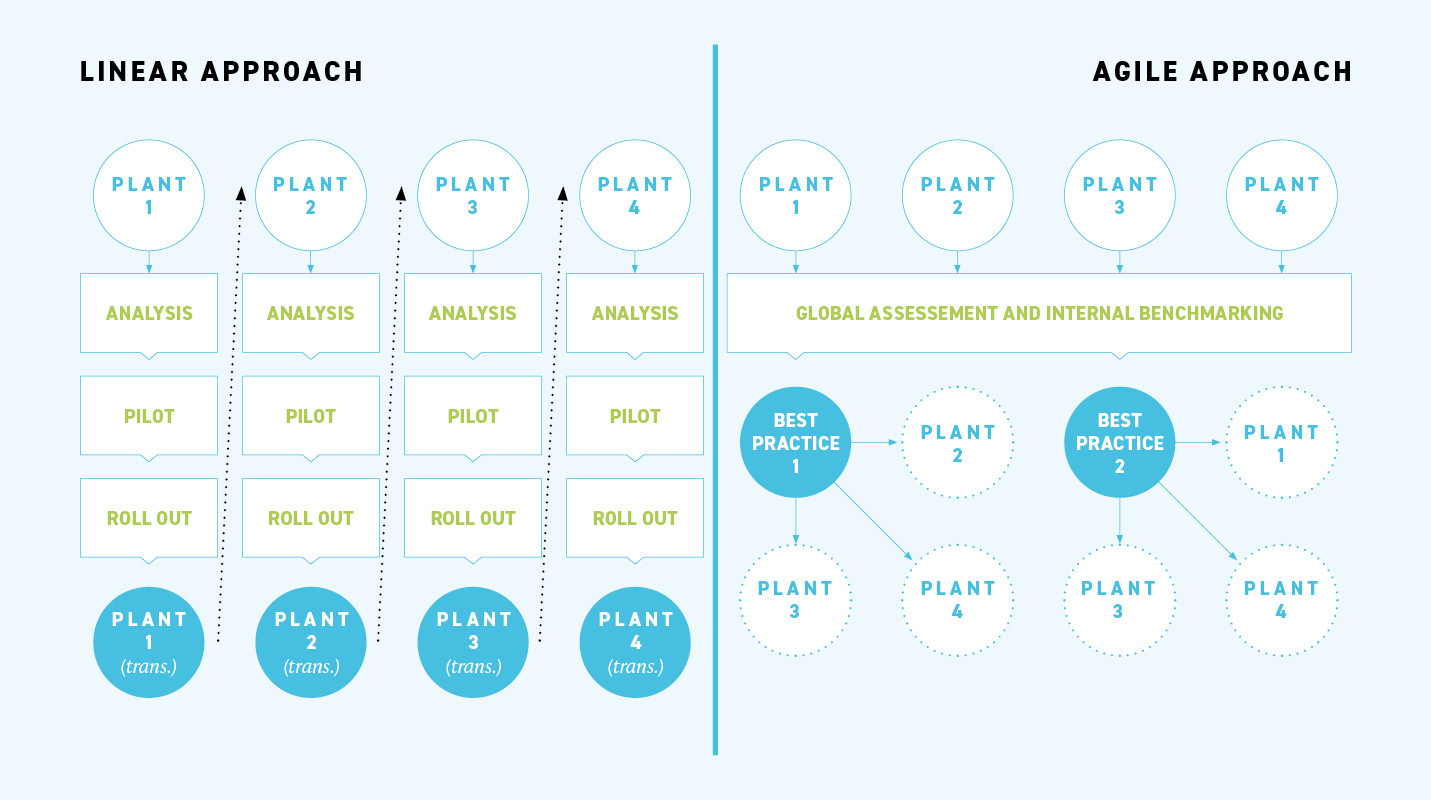

- Operational Excellence & WCOM

- Next Gen OPEX

- Zero-Based Organization

- Lean production

- Shop floor management

- Digital shop floor management

- TPM and OEE

- Quality and process stability

- Maintenance Excellence

- Factory and logistics planning

- Production planning and control

- Assembly and logistics

- IT management in manufacturing

- Digital Factory Twin

- Procurement

- Supply chain management

- Operations Footprint

- Product and Service Development

- Product Excellence

- Productivity increase

- Transformation & Leadership

- Sustainability

- Industries

- Insights

- Case Studies

- Learning Campus

- Join Us

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/dialog/59/ROI_layout_dialog__59_bilder_web8.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/dialog/59/ROI_layout_dialog__59_bilder_web10.jpg)