Experte:

Anna Reitinger |

07/25/2024

| Teilen auf in

How do you achieve new production levels, ensure the highest quality and link this specifically to progress in digital transformation?

Armacell is leading the way: With its “WAM = World Class Armacell Mindset” programme, the manufacturer of insulation materials and technical foams for industry is aligning 12 core elements of its organization towards continuous improvement. With 3,300 employees and 27 plants in 19 countries, the company has a global production network.

Christopher Borgmann, WAM Digital Transformation Manager at Armacell, and Christopher Martin, Senior Manager at EFESO, explain the goals, results and success factors of the program in the “Future Factory” talk with the online magazine produktion.de.

With EFESO's WCOM™ 4.0 approach, Armacell combines methods and technologies from two fields of action: “OPEX = Operational Excellence” and “Digitalization / Industry 4.0”. These are tailored precisely to the needs of the company.

WAM Scope: Getting better every day

“Continuous improvement - day by day” is the overarching objective of Armacell's WAM program. Similar to EFESO's “World Class Operations Management - WCOM™” approach, it currently addresses various management dimensions and 12 “pillars” of the organization, which are audited individually. These include, for example, safety, maintenance, supply chains, the environment and employee qualification.

Armacell therefore has a holistic approach to improving various company processes. Although WAM begins in the operations areas, it is not limited to these. Sales & Marketing and business processes in administrative corporate functions are also included.

Learn more: WCOM›

Synchronous instead of parallel: OPEX and digital transformation

Even an improvement program itself must sometimes be put to the test: Where can more / additional performance be achieved? What should be changed? Which influencing factors trigger improvements in the first place?

This is where the “bridge” to digital transformation arises, which is a significant influencing factor. Together with EFESO, Armacell therefore synchronized the change processes of the WAM program with those of the company's digital transformation. The goal: Developing and aligning auditable and measurable maturity levels in both transformations.

Learn more: Digitalization Excellence›

"It was particularly important to us that we had a partner at our side with expertise in the field of digital transformation. But at the same time, he also combines this with Continuous Improvement Operation Excellence, so that we definitely speak the same language."

Christopher Borgmann, WAM Digital Transformation Manager, Armacell

Strategy and implementation: Industry 4.0 maturity levels as guidelines

Methodologically, two elements proved to be critical to success in determining these maturity levels and achieving the corresponding results. Firstly, Armacell developed a target picture for one element of the program with EFESO. The results of a survey of top management provided the strategic framework for this.

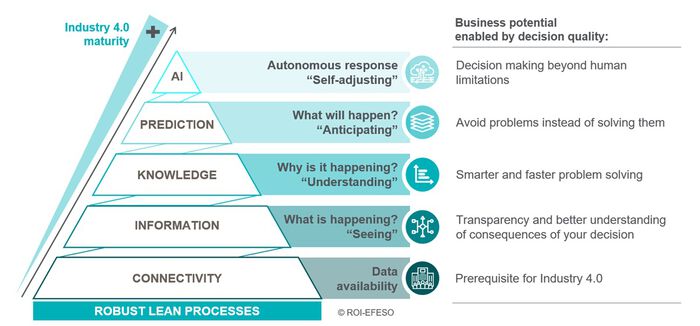

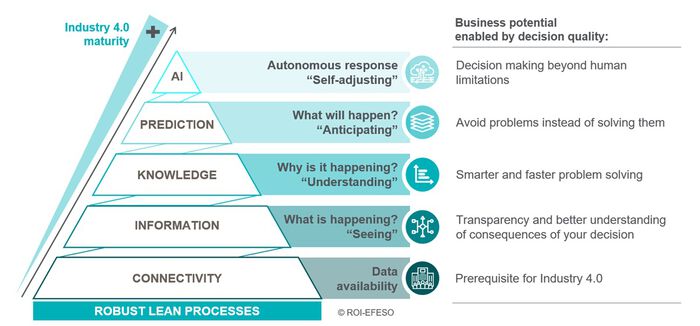

Secondly, the status quo in the plants was determined in order to harmonize both points. If the strategy is geared towards strict growth, for example, the program focusses on the search for potential that is conducive to capacity in the plant. A standardized procedure, in which improvement potentials are compared with the levels of the Industry 4.0 pyramid, delivers good results here.

WCOM 4.0 by EFESO

EFESO's proprietary World Class Operations Management approach (WCOM™) is already being used by around 160 companies worldwide. WCOM 4.0 combines the benefits of digitalization with a corresponding operations management system. As in the Armacell example, digitalization is thus implemented systematically and in a value-oriented manner in the factory or plant network.

Learn more: WCOM 4.0›

Practical experience

Essential “lessons learned“ from the implementation of Armacell's WAM program are:

- EFESO's cross-industry expertise in both focal points of the program ensured, that the right digital technologies were quickly identified and integrated into the day-to-day work of the Armacell workforce. For example, AI-based avatars could be used to convey the same training content in different languages (see video).

- Close, targeted cooperation between IT and operations teams is critical to success. The optimal focus is: How do you work together to successfully drive the digital transformation forward?

Also train your employees internationally with contemporary learning formats such as training avatars. The digital learning platform of EFESO's LEARNING CAMPUS enables customized learning in 140 languages and with over 120 avatars.

Learn more: Digital Learning Platform›