Developing smart products and services

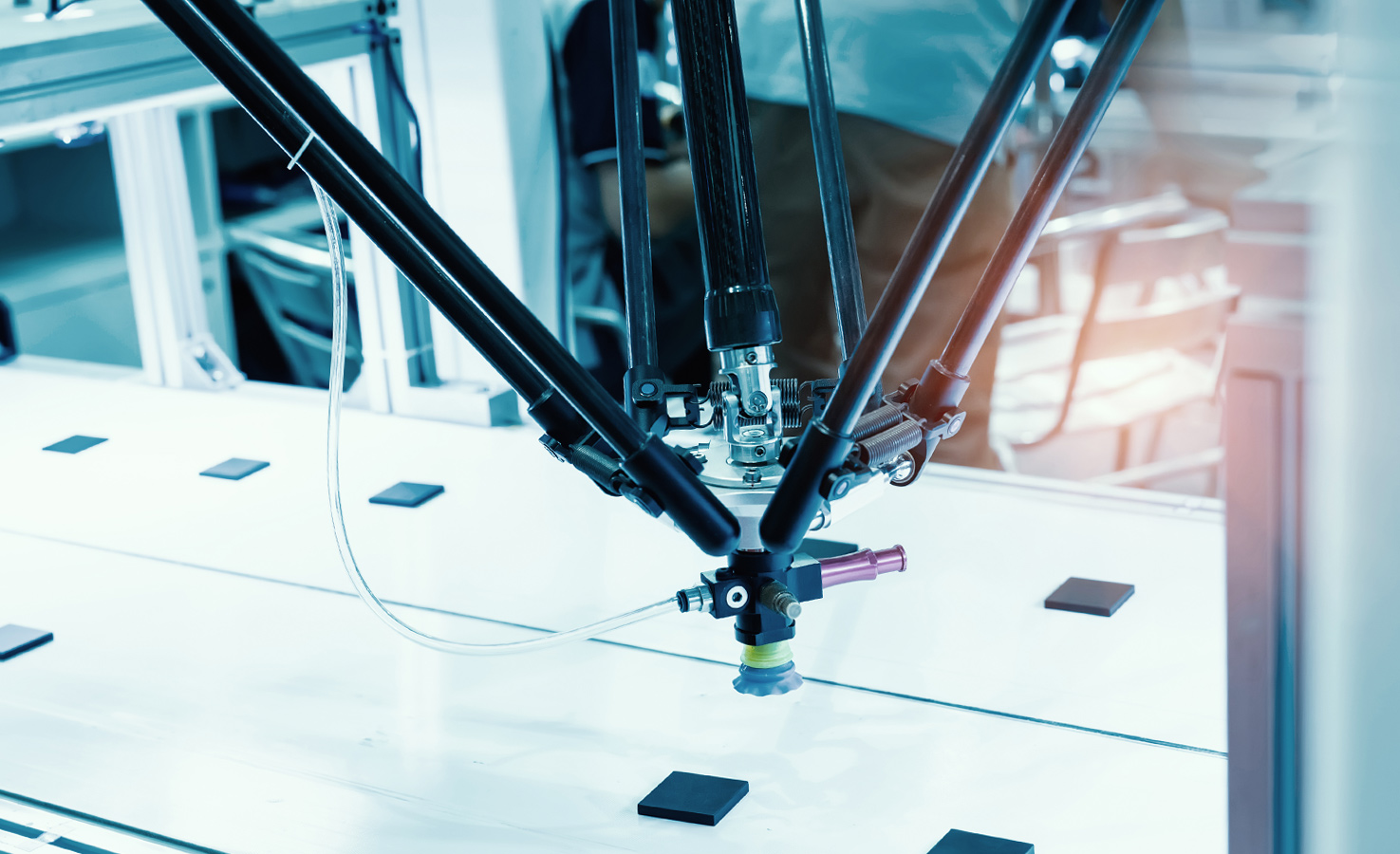

Smart products and services are at the core of most application scenarios in the Industry 4.0 or IoT environment. Smart products are characterised by the capability to collect and communicate data during their entire life cycle from the manufacturing process up to use by the end customer, or also to autonomously perform standardised tasks. Smart products develop their transformative effect, in particular, as elements in cyber-physical networks, platforms, clouds and ecosystems that are integrated by means of sensors, connectivity solutions and edge computing (decentralised computing at the network periphery).

Networks comprised of smart products form the prerequisite for intelligent, learning services (smart services). These are based on the aggregation and analysis of data collected from people, machines and processes and, in particular, allow individually configurable offers to be created by using targeted forecasts. Smart services can be used for the optimisation of repair and (remote) maintenance processes, for capacity planning and for ensuring business continuity, or for designing highly individualised service portfolios. In future, complex, innovative networks and transactions will be structured and controlled via decentralised and automated smart services.

In addition, the dimension of sustainability is becoming increasingly important in product design. Efforts to reduce environmental impacts along the product life cycle manifest themselves as profitable USPs in product characteristics such as durability, recyclability, reliability as well as minimal consumption of energy in materials, supplies and operating materials.

The development of smart products & services requires not only new forms of cooperation within the development departments, but also a variety of new structures, processes and competencies.

The consultants of EFSO have profound expertise and extensive project experiences in building the necessary processes, structures and capabilities for developing smart products & services. In particular, we focus on the following aspects:

- Interdepartmental and interdisciplinary data usage, system networking and system development

- Development of digital product and system concepts (digital twins, user interfaces, predictive analytics & maintenance)

- Introduction of agile, continuous and rapid development processes (MVP, design sprints, continuous product development)

- Agile software development and harmonisation of soft and hardware development and manufacturing

- Introduction and optimisation of big data analytics, as well as data administration, controlling and security

- Development of skills and recruiting in core areas such as software development, cloud computing, data analysis and service design, as well as modern development and project management methods